With more than 35 000 m2 on several sites, ALSYMEX offers a unique manufacturing capability including:

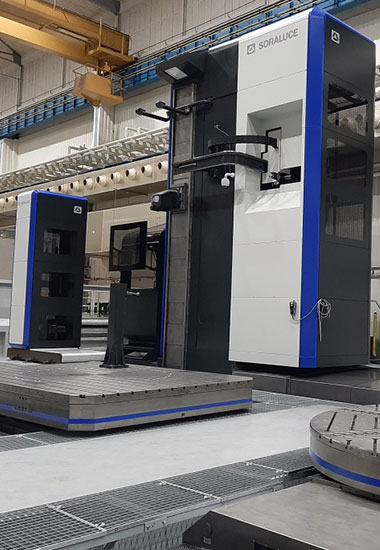

- Machining workshops equipped with turning (both horizontal and vertical), boring, milling and rectifying machines, presses and electrical discharge machines. One of these workshops is fully air conditioned (20°C ±0.5) and allows for machining of large dimension (up to 10 meters), high-precision parts

- 3D control rooms

- Welding workshops: EBW and LBW, TIG, MIG, Plasma, MIG on up to several mm thicknesses, folding and bending of metals and metallic tubes and pipes

- A 1 800 m2 clean room complex, including 600 m2 ISO5 and 300 m2 ISO8: integration of RF and opto-mechanical sub-assemblies, electrical and optical cabling, dimension controls, vacuum tests, optical characterization

A large variety of materials, including high-grade stainless steel, aluminium and alloys, copper and alloys, invar, titanium, tungsten and beryllium, are commonly worked with.

With these proven capabilities and industrial means, ALSYMEX can also deploy dedicated teams to customer sites to provide installation, commissioning and long-term maintenance services.